Learn

How Long Does a Medium Voltage Circuit Breaker Last?

Are you in charge of a circuit breaker? If you are a facility manager taking time out of your day to read this, you are likely aware of the importance of low, medium, and high voltage circuit breakers to the reliability of your electrical system.

Circuit breakers and fuses are the first line of defense against unexpected short circuits. If the electrical system is properly designed and maintained, circuit breakers and fuses will minimize the risk of electrical accidents and power loss. Yet, how reliable are circuit breakers? How long will circuit breakers last? How often should you do maintenance on circuit breakers? That depends on the age, type, usage, working environment, and maintenance program. In some cases, the impact of these variables is not intuitive. This article will summarize some of the limited studies available to help a facility manager make the right decisions about circuit breaker performance and preventative maintenance.

Circuit Breaker Type

According to a 2005 report from the US Army of Corps of Engineers Power Reliability Enhancement Program, the average failure rate of a circuit breaker is 0.83% or about 1 in 125. [1] (See Table 1)

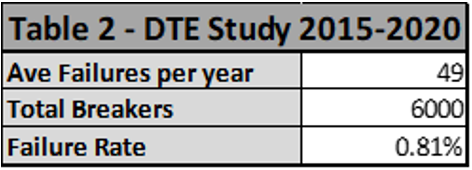

In DTE’s study [2], the average failure rate of breakers was like the US Army Corps of Engineers report at 0.81% or about one in 125. (See table 2) However, not all circuit breaker types have the same reliability. The Table 1 report showed that fixed molded case breakers were most reliable at 0.01%, or 1 in 10,000 failures per year, while SF6, showed a 132.61% failure rate, or 1. 3 per breaker failed per year. See the complete list of breakers in Table 1.

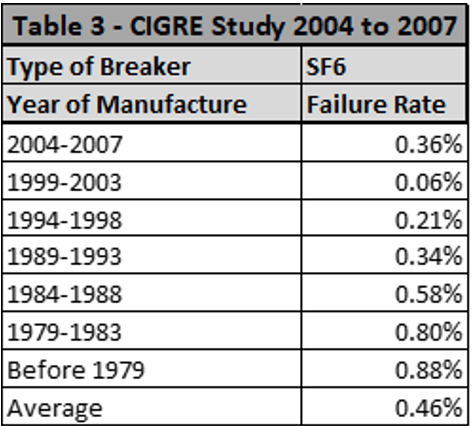

A second study CIGRE Study from 2004 to 2007 [3] on SF6 breakers found that their reliability was on average 0.46% or about 1 in 200.

Why was there such a big difference? One can only surmise that the reason is either the age, maintenance program, working conditions, or manufacture. In any case, circuit breaker experts have found that:

- Fixed molded case breakers are the most reliable, followed by

- Metal clad/air, vacuum, SF6, and lastly

- Oil filled

For this reason, fixed molded case breakers are growing in popularity while oil filled breakers are being discontinued.

Circuit Breaker Age

Referring again to the CIGRE Study [3], and Graph 1, the data shows the circuit breaker’s failure rate falls in the early years, usually due to manufacturing defects being rectified, then rises again as the breaker ages.

DTE found that the life expectancy of a circuit breaker is approximately 40 years for older circuit breakers. In comparison, more current breakers have a life expectancy of 30 years and are designed to be easier to maintain and replace.

Circuit Breaker Maintenance

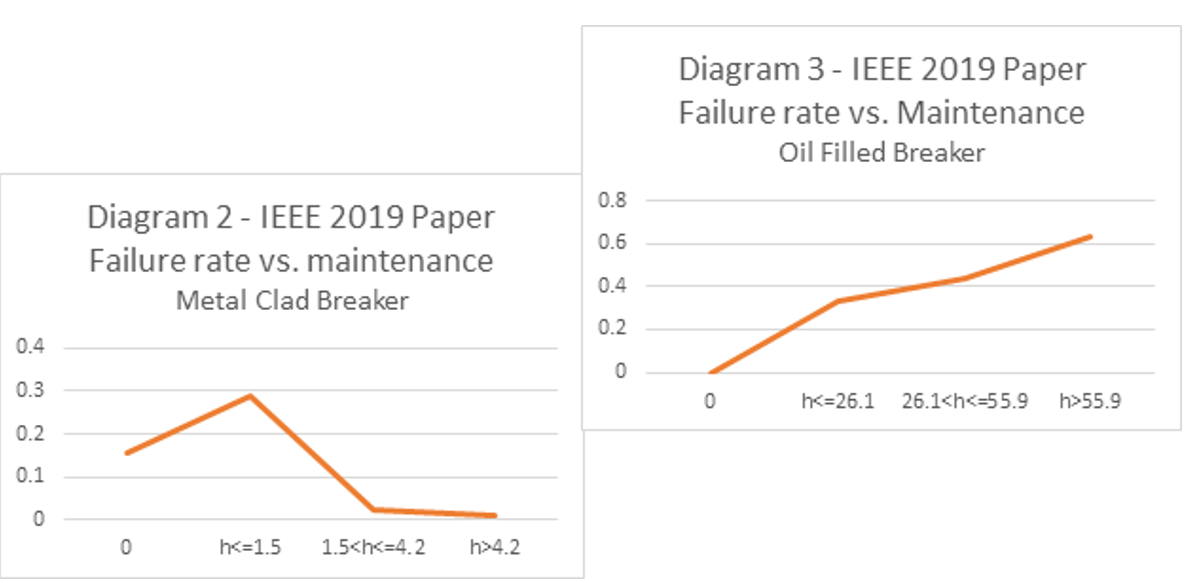

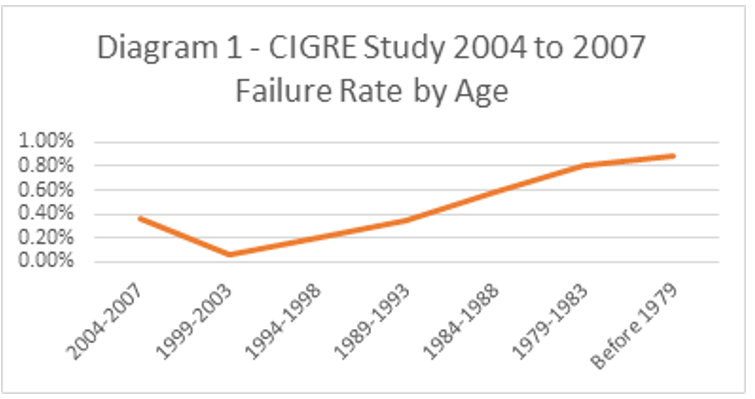

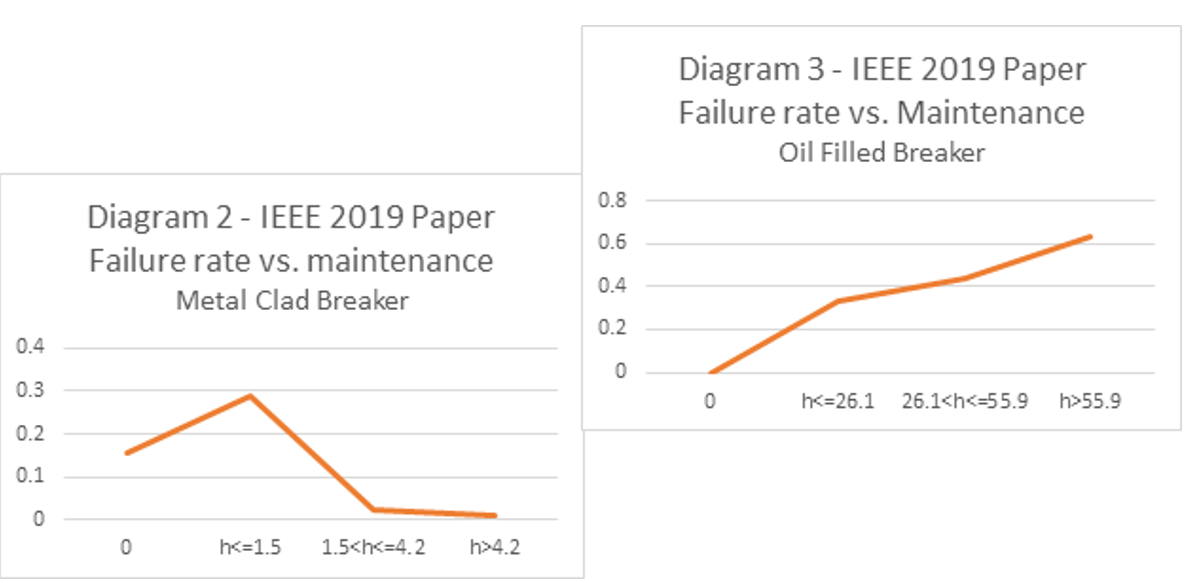

In a paper presented by IEEE [4], it was found that preventative maintenance has a significant impact on reducing failure rates for metal clad circuit breakers but not for oil filled breakers. See Graphs 2 & 3. Circuit breaker experts explained that the root cause of the rise in failure rate on oil filled breakers with increased maintenance is due to the significant amount of time and complexity of maintaining this type of breaker compared to other breakers. As mentioned earlier, oil type breakers are being discontinued.

Usage

Each circuit breaker is designed for a set amount of load and no-load operations. Refer to the manufacturer for this information. In addition, where it makes sense power users/generators monitor the qty of load and no-load operations on their SCADA system as part of their preventative maintenance program.

Working Environment

No papers were found comparing circuit breaker reliability in various working environments. However, our anecdotal evidence shows that in dirty or toxic environments such as those found in factories, steel mills, and water treatment facilities, failure rates will be higher if maintenance is not performed compared to clean environments such as hospitals and data centers. When planning your maintenance program, environmental conditions must be considered.

Conclusion

Facility managers are tasked with keeping the electrical infrastructure safe and reliable. A circuit breaker preventative maintenance (PM) program is an important part of this task. When developing the PM program, adjusting for circuit breaker type, age, usage, and working environment will mitigate the risk of plant downtime and electrical accidents while reducing electrical maintenance costs.

Learn more by downloading our Why, What, When, and Who of Electrical Maintenance white paper.

[1] – IEEE Std 3006.8 – 2018 [2] – DTE Electric Company – Distribution Operations Five-Year (2018-2022) investment and Maintenance plan Final Report [3] – IEEE Transactions on Power Delivery, Vol. 28, No. 1, January 2013 [4] – IEEE Transactions on Industry Applications, Vol 55, No. 6, November/December 2019

Need help developing your electrical maintenance program?

Call Team UIS – We offer a free preliminary assessment.