Learn

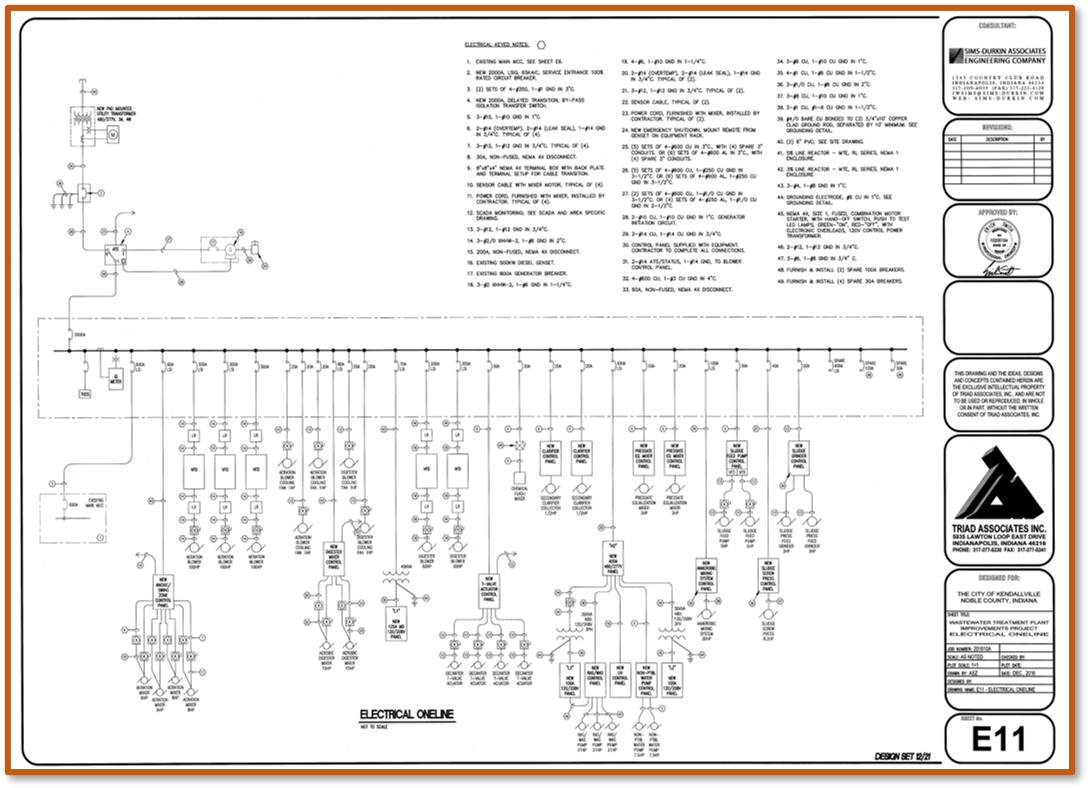

Do you Have your Electrical One-line?

Do you work in an electrically safe environment? Take our questionnaire and find out!

The Importance of Electrical One-Line Diagrams in Emergency Situations:

Emergencies can occur unexpectedly, posing risks and potentially leading to costly consequences. To mitigate these risks, it is crucial for facility managers to be prepared. When an electrical emergency strikes, one of the first questions asked by electrical testing companies is whether the facility manager has their electrical one-line diagram. An electrical one-line serves as a blueprint, illustrating the connections of electrical equipment within a facility. Having this diagram readily available significantly aids technicians in responding swiftly and effectively to troubleshoot the emergency.

Troubleshooting Approach: When faced with an electrical emergency, it is essential to follow a systematic approach to identify the root cause of the problem. Some key questions to consider during troubleshooting include:

- Assessing the Scale of the Issue:

- Is the entire plant experiencing a power outage?

- Is the power outage isolated to a specific building?

- Is the power outage limited to a Motor Control Center (MCC)?

- Is the power outage confined to a particular piece of equipment?

- Equipment Status:

- Was the equipment running when the problem occurred?

Applying basic troubleshooting techniques helps determine the exact problem and facilitates a more accurate solution. Similar to a person experiencing a headache, where the underlying cause could be various factors, it is crucial to identify the precise issue to resolve it effectively. Sometimes, a process may encounter multiple minor problems while still operating at a degraded level.

Benefits of Having an Electrical One-Line Diagram: Having an up-to-date and easily accessible electrical one-line diagram offers numerous advantages in emergency situations:

- Time Savings:

- By providing technicians with a clear overview of the electrical system, troubleshooting time is significantly reduced.

- Cost Savings:

- Swift identification of the problem and targeted repairs minimize downtime, reducing the financial impact on the organization.

- Enhanced Safety:

- A comprehensive electrical one-line diagram enables technicians to identify power sources accurately and perform lockout-tagout procedures confidently, ensuring a safe working environment.

In times of emergency, being well-prepared is paramount to minimize risks, costs, and downtime. An electrical one-line diagram serves as a crucial tool for facility managers and technicians, aiding in efficient troubleshooting and ensuring the safety of all involved. By having this blueprint readily available, facilities can respond promptly to electrical emergencies, effectively mitigate potential damages, and restore operations swiftly. If power needs to be shut off by the electrical company, a one-line will show where that power is coming from. If a lock-out tag out needs to be performed to troubleshoot the issue, this can safely be performed with confidence after reviewing the electrical one-line. Safety is a priority, especially in a stressful emergency.

To dive deeper into the subject, download our comprehensive white paper titled “Why, What, When, and Who of Electrical Maintenance.” It provides valuable insights into the importance of electrical maintenance and highlights best practices for maintaining a safe and reliable electrical system.