Electrical Preventative Maintenance

Why do it?

Deterioration of the electrical system that delivers power to facilities is normal and failure is inevitable. According to two studies, one in 200 transformers and one in 100 breakers fail every year. In addition, the Electrical Safety Foundation International reports that in 2018 there were 160 electrical deaths and 1,560 electrical injuries. Most of these catastrophes can be avoided with a routinely planned EPM program. In sum, EPM program makes the power system safer, more reliable, and in many cases reduces insurance costs. Click here for a paper on EPM.

How to proceed

Team UIS has experts that can help facility managers develop a custom Electrical Preventative Maintenance plan. Call or email our experts to get started.

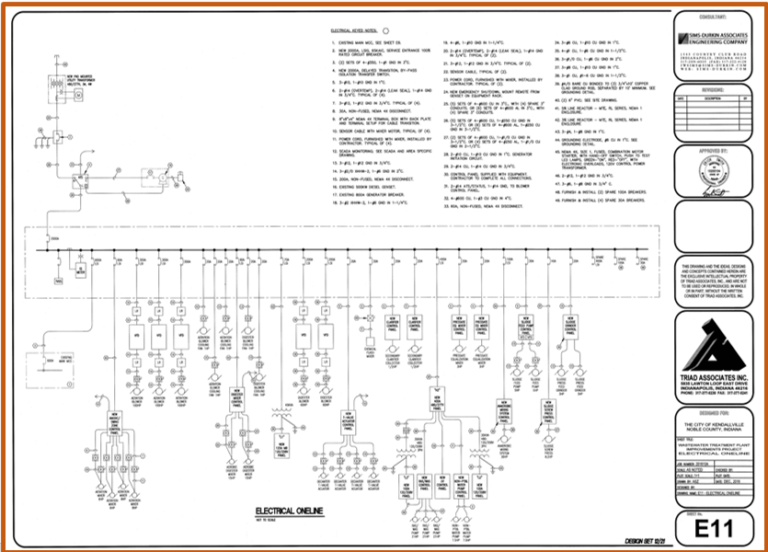

They will require an up-to-date one-line drawing of your facility and in most cases will conduct a phone interview with you. If you do not have an up-to-date one-line drawing, they can send someone to your facility to create one. See the example below.

Typical Preliminary Report

After the phone interview, or in some cases a visit, the experts will provide a recommended PM program that will consist of:

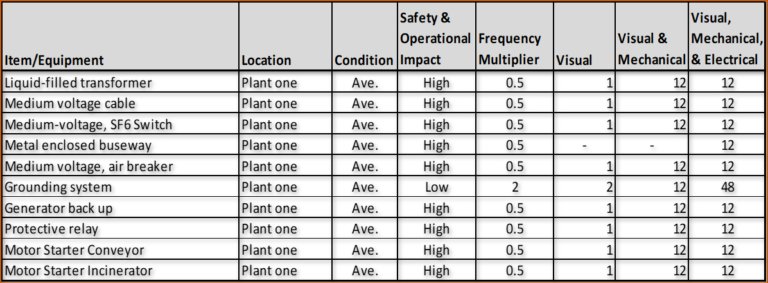

A list of electrical equipment, their condition, their safety & operational impact, the frequency of maintenance. It may include the table below. This is created using the ANSI/NETA Maintenance Testing Specifications.

Proceeding with Electrical Preventative Maintenance

The essential factors in a proper and comprehensive EPM are:

1. Performed by Qualified Technicians with high safety standards

A proper and comprehensive EPM requires qualified technicians who are certified by recognized electrical testing firms such as NETA. These technicians dedicate their careers to electrical testing. They are routinely trained on best practices for safety and electrical maintenance and perform their tests using the best equipment available.

2. A detailed electrical maintenance plan

The plan will list all the apparatus that will be tested, the recommended frequency, and the appropriate test that will be performed.

3. Comprehensive electrical maintenance test report

The report will provide all the test details, found deficiencies, and recommended corrective measures.