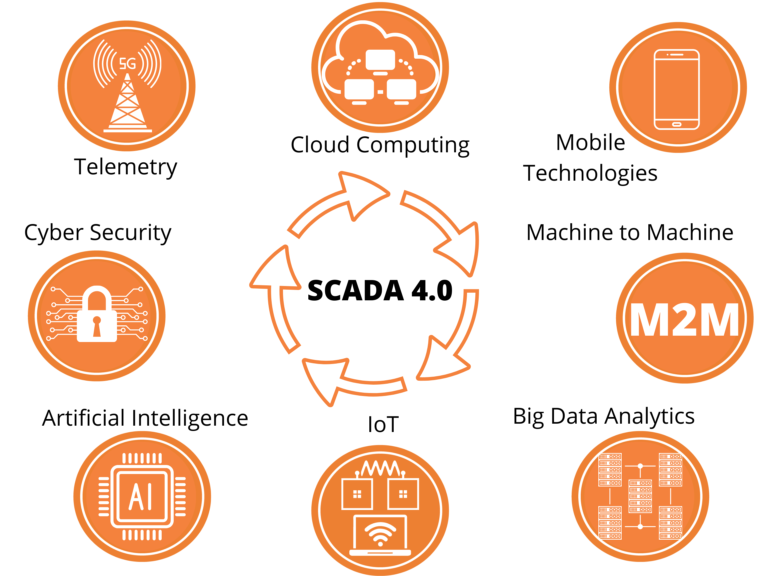

What is SCADA 4.0?

Industry 4.0 is the Fourth Industrial Revolution. SCADA 4.0 is the application of Industry 4.0’s technological revolution to SCADA. It is fundamentally changing the way water and wastewater treatment facilities and their operators are functioning. See the picture below.

How can SCADA 4.0 help water and wastewater operators?

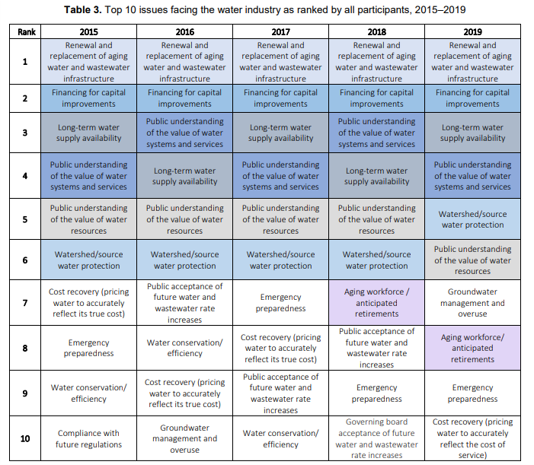

The AWWA reports annually in its State of the Water Industry Reports the top ten issues 10 issues facing the industry. Below is the list for the past five years.

SCADA 4.0 provides tools to help in each of these ten issues.

1 – Renewal and Replacement of Aging water and wastewater Infrastructure.

Creating a credible asset management program requires asset performance data. By synchronizing the SCADA system to an asset management program helps optimize both asset replacement and maintenance.

2 – Financing for Capital Improvement

A persuasive case for financing for capital improvement requires asset performance data combined with maintenance costs. SCADA’s ability to collect performance data such as pump failures, water losses, and power consumption, 24 hours a day, 365 days a year, helps generate this critical data.

3 – Long-term Water Supply Availability & 7 – Groundwater management and overuse

Having years of trending data on the level of water sources from a SCADA system is vital information for engineers tasked at forecasting long-water supply availability.

4- Public Understanding of the Value of Water Systems and Services & 6 – Public Understanding of the Value of Water resources

An effective public education campaign on this subject is greatly enhanced if key water and wastewater performance information can be made public. This information would help impress the important work being done by the operators. SCADA 4.0 can feed key data to a website accessible by the public and, in some cases, displayed on a screen at City Hall.

5 – Watershed/source water protection

An effective watershed/source water protection program has proper monitoring and warning systems. SCADA 4.0, with advanced telemetry, provides this capability.

6 – Aging Workforce/anticipate retirement

It is an increasingly greater challenge to attract talent to operate water and wastewater facilities. An effective SCADA system helps accelerate the training of the next generation. Process flow graphics, map overviews, equipment performance, alarm management, and other SCADA features help diminish the fear of operating the facility and persuade that talent to join the team.

7– Emergency Preparedness

A thorough emergency preparedness plan is well beyond the scope of a SCADA system. However, early warning required to initiate an emergency plan is essential. This is the role SCADA 4.0 plays in an emergency preparedness plan.

8 – Cost Recovery (Pricing water to accurately reflect the cost of service.)

A SCADA system with well-maintained and calibrated instruments provide exact flow rates. This is an essential variable to establish the proper cost of water supply.

Are Utilities Implementing SCADA 4.0 Technologies?

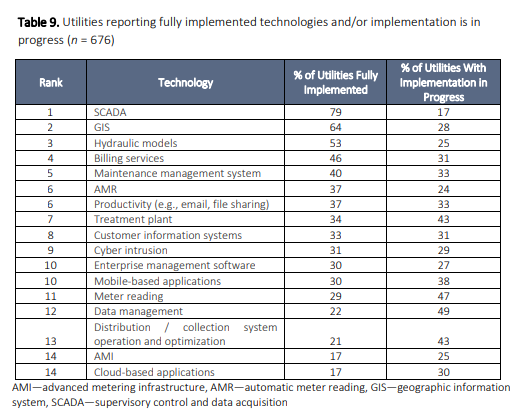

In 2018 the AWWA polled water and wastewater operators on the status of technology implementation. Below are the results. They show how SCADA 4.0 technology is being actively implemented.

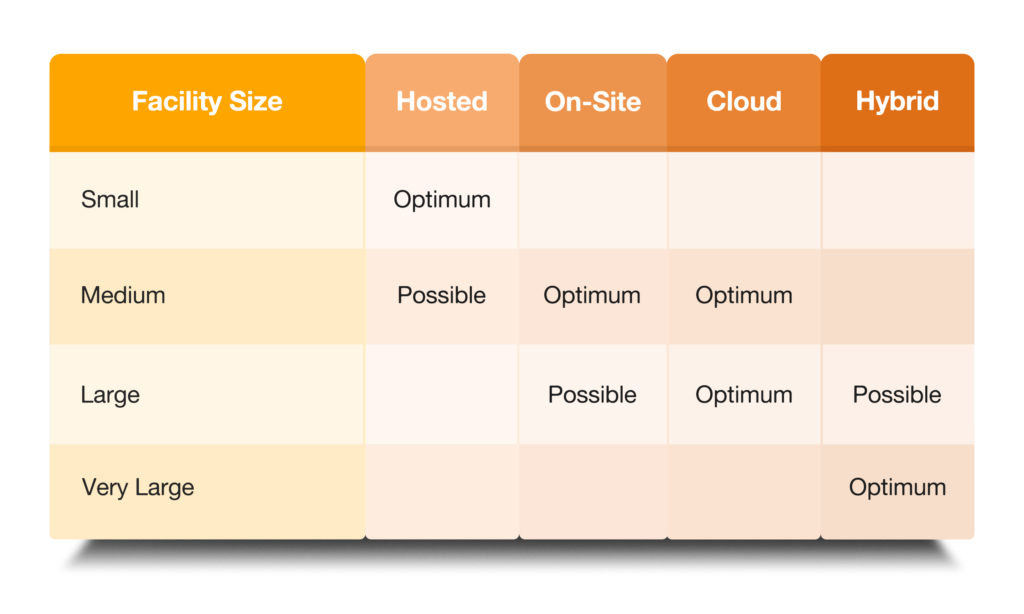

Hosted, on-site, cloud, or hybrid SCADA? What makes sense?

- All options are viable options depending on a facility’s circumstances. What drives the decision is the cost of the system and the need to bring SCADA in house.

- A hosted SCADA system is a cloud-based system hosted by the integrator.

A small facility that does not have the resources to purchase the full SCADA software/hardware package yet would benefit from the power of a SCADA 4.0 is an ideal candidate for a hosted SCADA system. On the other hand, a very large facility that wants all the benefits of a cloud base and on-site system, ought to consider the hybrid option. Talking to an integrator that offers all options is a good place to start.