Learn

When should instruments be calibrated?

When was the last time your equipment was calibrated? Are their calibration stickers on your instruments? Is it time to do calibrations? This paper gives the operation team a template to develop a comprehensive calibration plan.

If your plant is like most, the demands on plant Superintendents or Operators are increasing, staff is diminishing, budgets tightening, and your processes are getting increasingly more complex. Managing a high-performance cost-effective plant requires a comprehensive calibration plan that covers what needs to be calibrated, how it needs to be calibrated, and how often. A comprehensive calibration program is typically developed with the help of an experienced municipal water and wastewater calibration technician. Such a program provides the operating team with confidence codes are met, regulatory and production reports are accurate, plans are well documented, processes are efficient, and alarms are real. Thus, assuring the trust of residents and peace of mind for the operating team.

What does a Calibration Technician do?

Calibration Technicians are trained by organizations such as the Electrical Power Research Institute (EPRI) or International Society of Automation (ISA). They bring calibration equipment that are also calibrated annually and traceable to the National Institute of Standards and Technology (NIST). This assures the plant operation team that instruments are precise, accurate, and repeatable.

Using an experienced municipal calibration technician mitigates risk. A Calibration Technician that knows water and wastewater processes will help identify the instruments that require calibrations, the frequency that calibrations are required, the most cost-effective way to do calibrations, and do necessary instrument programming and repairs.

Developing a Calibration Plan

A “Best Practices” calibration plan requires the guidance of an experienced calibration technician. There are 7 steps a calibration technician will follow to develop a calibration plan.

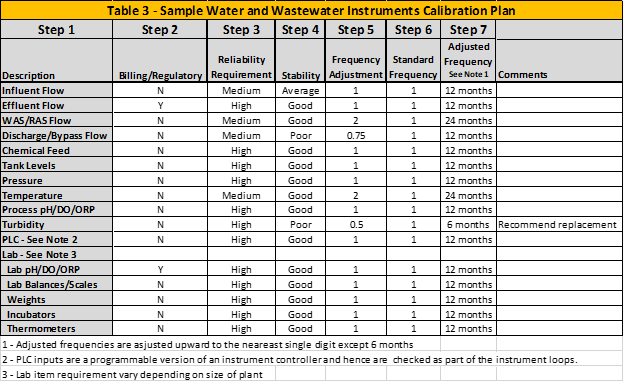

1 – List all the instruments that require periodic calibrations. See Table 3. If you are not sure, we recommend contacting experienced municipal calibration technicians to help you identify the instruments that are typically calibrated.

2 – Determine which are billing or regulatory instruments. Enter Y or N on the Step 2 column of Table 3.

3 – Determine the level of instrument reliability requirement of each instrument. If the instrument is used for Billing or Regulatory purposes, the reliability requirement is always High. Enter High, Medium, or Low on the Step 3 column of Table 3.

4 – Determine the stability of each instrument. This depends both on the age of the instrument and manufacturer’s recommendations. Enter Good, Average, or Poor on the Step 4 column of Table 3.

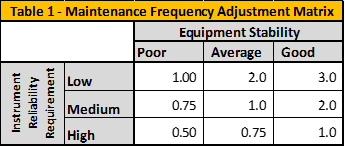

5 – Using the input from step 3 and 4 and Table 1, input the frequency adjustment on step 5 column of Table 3.

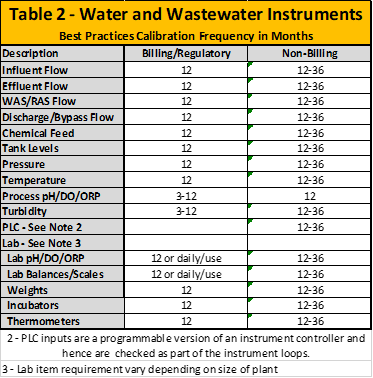

6 – Using table 2 input the best practice standard calibration frequency. These figures are the most common practices. They can be adjusted to manufacturer’s recommendations. Enter it on Step 6 column of Table 3.

7 – Using Table 3, complete the final column using the inputs from Step 5 and 6.

Calibrating Outside the Calibration Plan

Despite having a good calibration plan, there are times when calibration need to be performed outside the plan. This can be following a damaging event such as a collision, after major equipment modifications, or after electric shocks. All these events can cause visible and invisible damage to the instrument.

Learn More

A great calibration program delivers residential trust and peace of mind. Call on an experienced Calibration Technician to help develop your calibration program and perform your periodic calibrations. Learn more by reviewing our White Paper on Municipal Calibration Programs.