Learn

Why is Calibration important?

Why is it important to keep up on instrument Calibration you ask?

Calibration will help prevent:

- Equipment Failure

- Unexpected Emergencies

- Repair costs

The possibility of getting fined for unexpected discharging, blowers and pumps failing prematurely, basements flooding, and water towers running unpredictably empty during a fire emergency are all real-life events that can be avoided. A good calibration program mitigates these, and other costly emergencies, repair costs, and regulatory infractions.

Whether you work in water or wastewater, you are part of a team that is responsible for the safe and reliable delivery of clean water. If your facility is like most water and wastewater facilities, regulatory demands are rising, staff levels are diminishing, systems are getting more complex, and your most experienced staff is either retiring or close to retiring. In addition, unlike manufacturing, chemical, or other process-driven businesses, you can not stop the process for a holiday or a weekend. You and your team can not work 24 hours a day. You need the means to know how the system is performing at all times and when the wheels start to get wobbly or fall off. You need reliable data feeding your control systems. That is only possible if instruments are routinely calibrated and maintained.

Calibration

Part of the best practices program that mitigates costly and possibly catastrophic failures in your processes is calibration. With calibration, you are comparing the performance of your instruments to well-established and well-regulated benchmarks to ensure that your equipment is performing as expected. The known instrument used to perform these calibrations is traceable to a nationally recognized metrological institute such as the National Institute of Standards (NIST) in the United States.

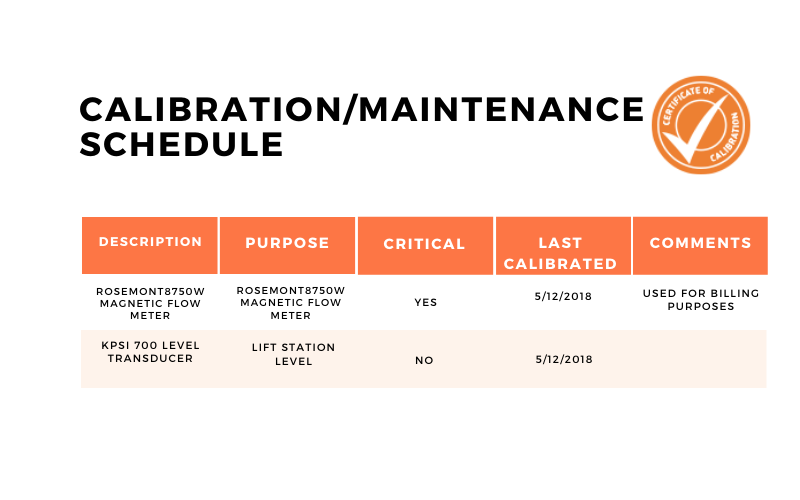

Building a Calibration/Maintenance Schedule

All instruments have a limited operational life; hence all instruments require routine maintenance which includes calibration. When creating a calibration/maintenance schedule, create a table like the one below listing all process instruments. We recommend that you identify which is critical, e.g. used for the billing process, or performs a function where accurate measurement is necessary, such as chemical feed flow.

• Note that in some cases the PLC will need to be calibrated and should be on the list.

• The table below lists a typical format for listing all instruments.

Instrument calibration is an essential tool to understand the present performance of your machines while avoiding future issues that may arise which are otherwise preventable. It cannot be overstated enough how important it is to calibrate your instruments regularly. This will help reduce those unexpected and costly emergencies that cause downtime.

Instrument calibration is an essential tool to understand the present performance of your machines while avoiding future issues that may arise which are otherwise preventable. It cannot be overstated enough how important it is to calibrate your instruments regularly. This will help reduce those unexpected and costly emergencies that cause downtime.

Learn More

To learn more about the why, what, when, and who of Calibrations, download our white paper.