What is SCADA?

SCADA is an acronym for Supervisory Control And Data Acquisition.

The acronym SCADA was first used in the 1970s to describe a system that simplifies increasingly complex controls systems with a multitude of PLCs, sensors, and switches. SCADA provided a single human to machine interface for controlling and monitoring the process.

Today, SCADA is everywhere. The temperature control in your home, the water you drink, the car you drive, the gas you pump, the power you use, flights you take, and much more depend on a SCADA system.

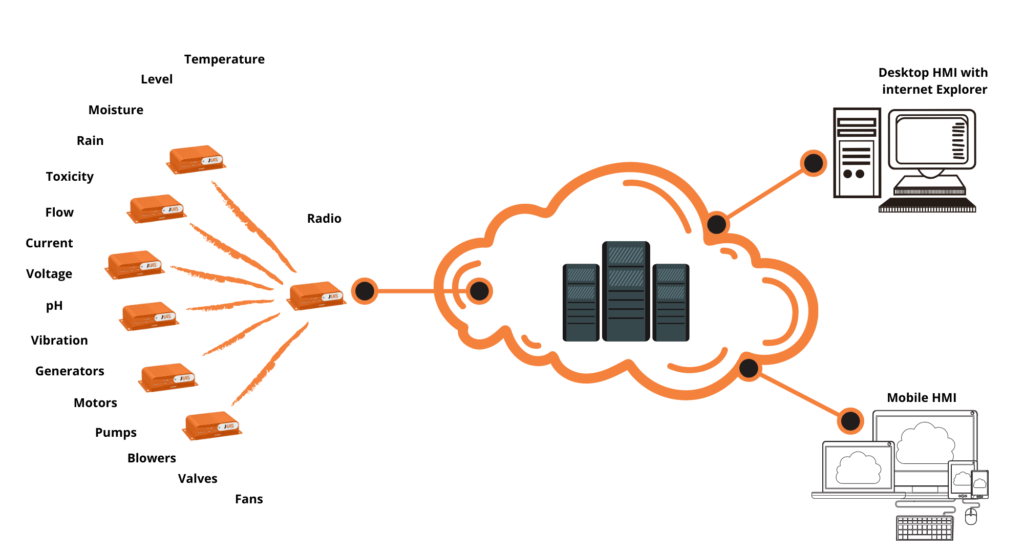

The components that make up most SCADA systems are:

- Sensors to monitor a process

- Control mechanisms to change the process (Flow, level, and temperature)

- Remote Terminal Units (RTU) or programmable logic controllers (PLC) to collect the sensor data and send commands to the control mechanism

- Telemetry in the form of ethernet, cell, fiber optics, radio, satellite, or landlines to deliver the data to a central location

- A data concentrator to collect data from multiple RTUs

- Human Machine Interface (HMI) or workstation that delivers data and control capability to an operator. This is where the SCADA software is used.

Some of the benefits of a SCADA system are:

- Peace of mind from having an artificial intelligence watch over the system

- A geographical map of all active sites with an RTU/PLC showing normal and alarm conditions

- A graphical dashboard of all processes and their status

- Alarm management calls when a process variable is outside of norms

- Early warning predictive maintenance to mitigate catastrophic failures

- Real-time process data for remote control, optimization, troubleshooting, and trending

- Auditable historical process performance data and automatic reports

- Secure access from anywhere anytime

- Lower labor costs and less process downtime

- Optimized maintenance programs by synching SCADA to asset management software

- Secure graphical web visibility for processes that can be shared with the public