Learn

What is SCADA?

SCADA is an acronym for

Supervisory Control And Data Acquisition.

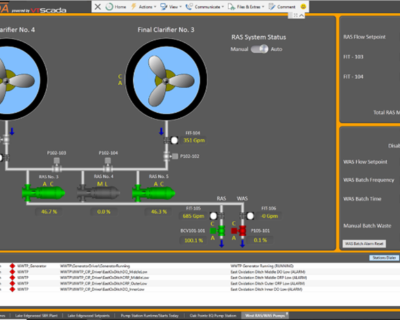

The acronym was first used in the 1970s to describe a system that consolidates complex control systems that use a multitude of PLCs, sensors, and switches. SCADA provides a single human-machine interface (HMI) for controlling and monitoring assets and processes.

Other terms that describe similar functions are:

Distributed Control Systems (DCS): typically used when all assets are in one building

Data Acquisition Systems (DAS): This is a simplified SCADA system requiring no control.

Some of the benefits are:

Primary

- Automatic emergency callout to system operators for fast response to system emergencies before significant damage occurs

- Easy human interface of the process being controlled and monitored

- Early warning predictive maintenance to mitigate emergency or catastrophic failures

- Data source for cost-effective asset management, process optimization, trending, and troubleshooting

- AlwaysOn™ robotic monitoring operator to reduce the need for 24-hour staff

Secondary

- A geographical map of all active sites showing normal and alarm conditions

- A graphical dashboard for each active site showing the status of all process variables

- Auditable historical process reports

- Automatic delivery of routine reports

- Secure access from anywhere, anytime

- Lower labor costs and less process downtime

- Optimized maintenance programs by synching to asset management software

- Secure graphical web visibility for processes that can be shared with the public

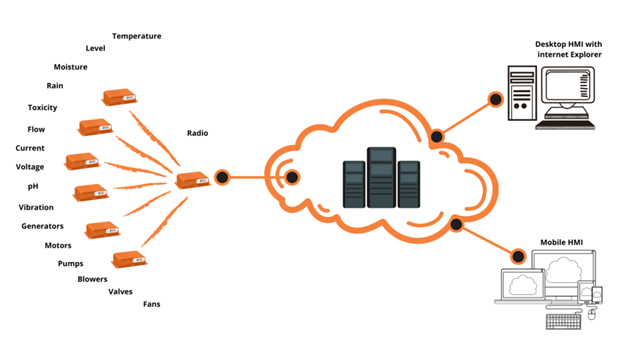

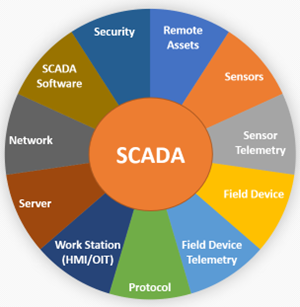

The SCADA components

- Remote Assets

- Sensors

- Sensor Telemetry

- Field Devices

- Field Device Telemetry

- Protocols

- Workstations

- Servers

- Network

- SCADA Software

- Security

A SCADA system uses a network protocol or computer language to communicate with the field devices.

Categories

- Polling – Initiated by the server and delivers data points – Examples are Modbus, Profibus, DF1, Ethernet IP, Siemens, GE, Omron

- Report by exception – Initiated by the field device and delivers data points – Examples are CANBUS, MQTT, OPC

- Advanced – Initiated by either report by exception polling, delivers data packets, maximizes security – Examples are DNP3 and IEC 60870

Workstations & Local HMI

Options for accessing the SCADA network have exploded. Workstations and local HMI can be a standalone computer network (common), thin clients (less common), cell phones, tablets, touch screens connected to field devices, and any other internet-connected device.

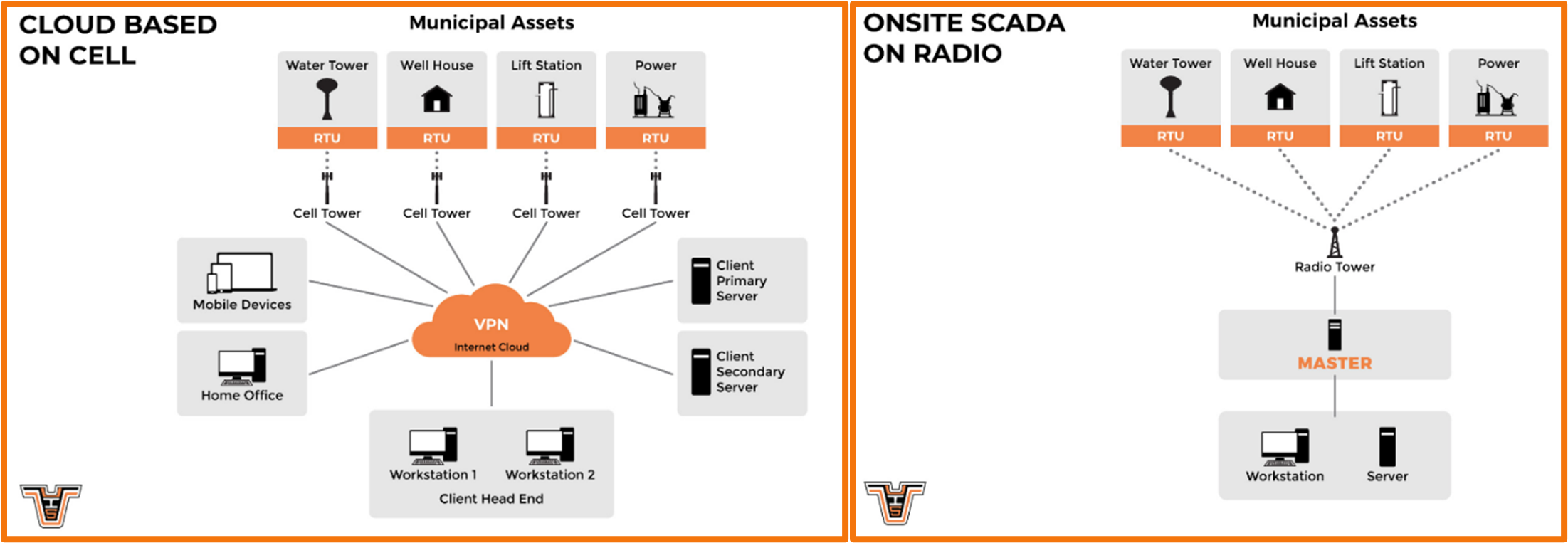

Servers

This is where the software resides. The server manages access to SCADA, data collection, SCADA programming, security, and many other SCADA administrative and configuration functions.

It is best practice to have two servers and routine backups for maximum security and reliability. These servers can be onsite or in the cloud through third-party vendors.

To learn more about servers, check out our CRUISE page.

Summary

Today, SCADA/DCS/DAS is everywhere. There are many benefits, such as: raising the quality of life and lowering operating costs. The temperature control in your home, the water you drink, the car you drive, the gas you pump, the power you use, the flights you take, and many more rely on the SCADA system.

Adding to your current system or investing in a new system is a favorable decision for your facility.

Learn More

For a deeper dive into SCADA, please download our white paper: SCADA 101 to learn more.